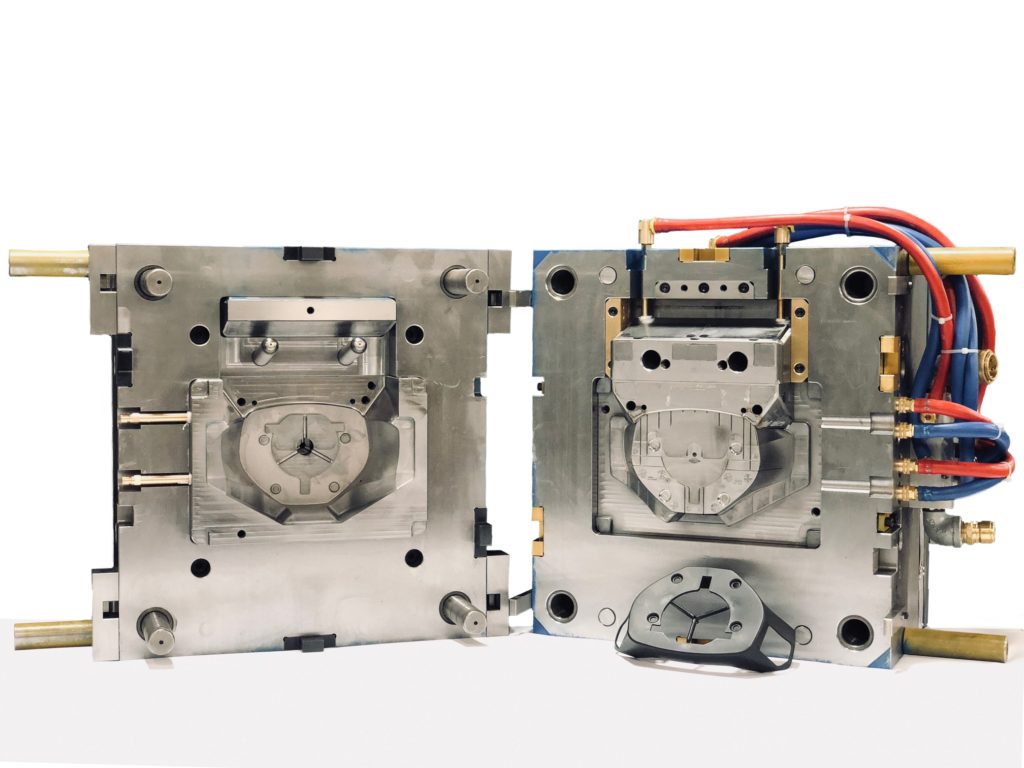

Mold Making & Tooling

From Prototype To Production

Eclipse Mold's in-house prototype division allows us to decrease the time it takes for your vision to get into production and onto the market. In as little as 5-7 days, we can build an aluminum mold that is ready to shell out production-quality parts. Fully automatic bridge molds can be built in four weeks, whereas hardened S-7 multi-cavity production tools can be ready in an average of 6 to 8 weeks.

Experience & Technology

Most members of the Eclipse Mold team have at least a decade of mold-building experience under their belt. This dedicated experience, merged with the latest technologies From Makino, allows us to utilize the latest software from MasterCam, Powershape and Delcam products to produce volumetrically accurate molds yielding a precision performance to help create profitability to our customers.

Global Partnerships

Eclipse has taken the lead in partnering with Asian suppliers for 20 years. With partners in China and Korea, we have searched for partners with the same technology and taught them the "Eclipse" way of building a tool. Combined with our knowledge of injection molding and program management, we create extended value beyond our shores.